Developed for attaching a 50AWG tri-filar wire to a miniature pressure sensor .2mm wide, with traces on the sensor being .06mm apart. Several techniques were employed in the R&D phase including laser welding, hot air, and induction heating, however resistance welding was found to be the most economical and reliable method for attaching the wires.

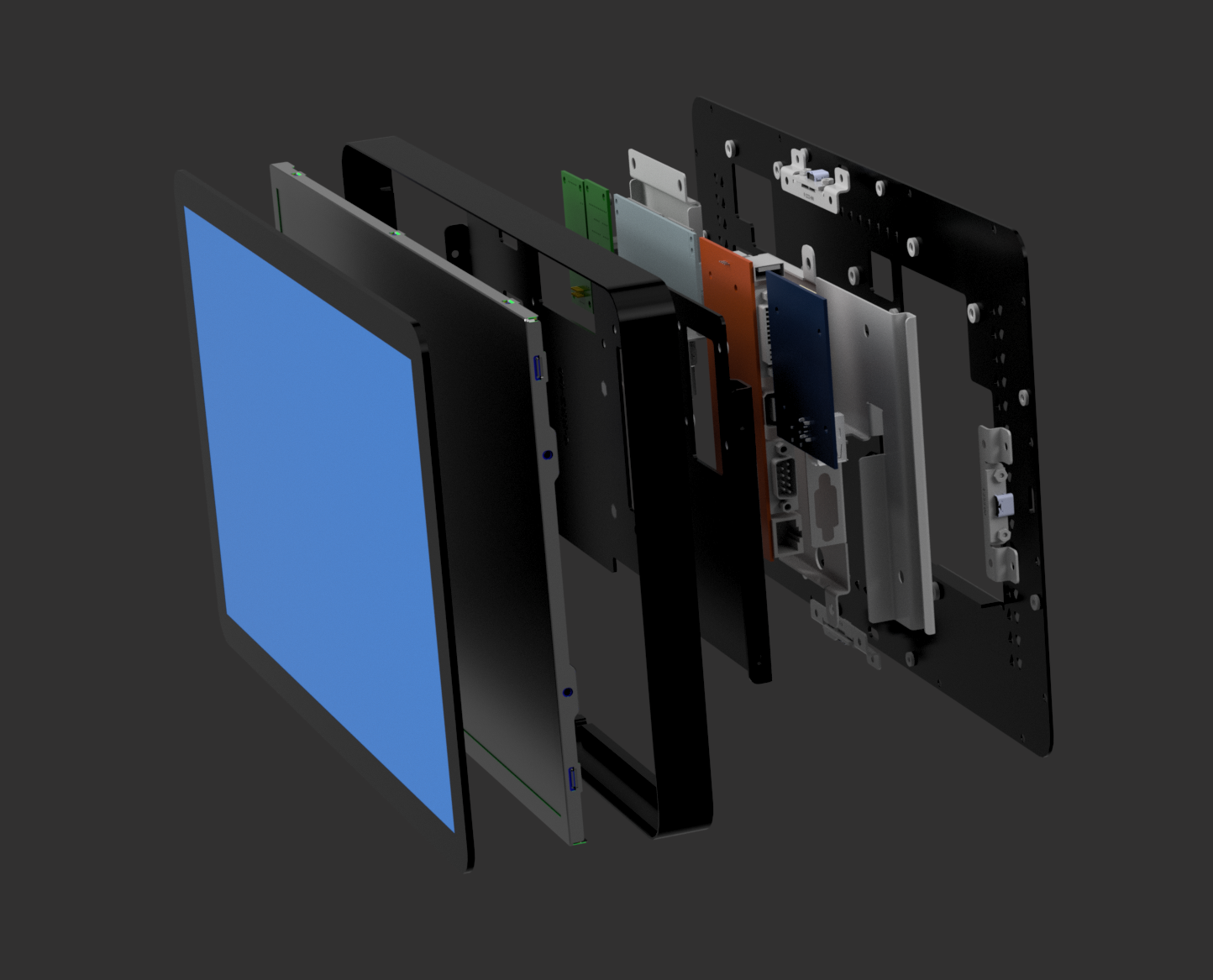

Custom Monitor Builds

Engaged directly with customers to gather requirements, establish budgets, and define project deliverables. Organized and ran regular update meetings to keep the timeline on track and address any challenges proactively. Facilitated weekly meetings with our Vietnam manufacturing team, ensuring alignment on production schedules, quality, and prototyping. Developed and implemented systems and processes that standardized and streamlined custom development projects.